Stretch films – transparent or coloured?

Stretch films are used in every industry – be it manufacturing, logistics or processing. It is a material that perfectly protects products and is easy to use. Classic stretch films are transparent and originally served as a material for securing goods on pallets. Today, they have a much broader application – protecting products of any size. The transparent film facilitates identification of wrapped goods. Transparent films are used, for example, in the catering industry. Food grade film is dedicated to them. Transparent stretch film allows assessment of the condition of the wrapped product and control of its further storage process.

Transparent stretch film on arm wrapping machine

Transparent stretch film has no masking properties, so it is not used where the user needs to hide the contents of the load. In response to these expectations, stretch film manufacturers offer coloured stretch films which, due to their colour, are classified as opaque films. We offer stretch films in various colours – including black stretch films, white and blue. These films fully cover the load.

How are coloured stretch films produced?

We produce our stretch films using the CAST method. Coloured films are created by adding a colour concentrate to the film production. This allows us to achieve the appropriate level of coverage and colour. The dye is distributed throughout the film, which ensures a good level of coverage even when the material is stretched.

Stretch film granules – from left: black, white, blue and transparent.

For the production of coloured films, we use the M50 process line specially designed for this purpose – in particular, we recommend multilayer black machine stretch film and jumbo film.

Stretch film colours in the Efekt Plus range

Stretch films in various colours are offered primarily to those wishing to mask the load being transported or stored. Thanks to this, we can maintain discretion and protect ourselves against the potential risk of theft or damage to goods. Coloured film also has the added benefit of providing additional protection against light radiation from the wrapped goods.

In northern countries, where low temperatures prevail, we recommend colour stretch films in combination with Frozen™ finishing. This ensures that the wrapped load is better protected against rapid temperature fluctuations.

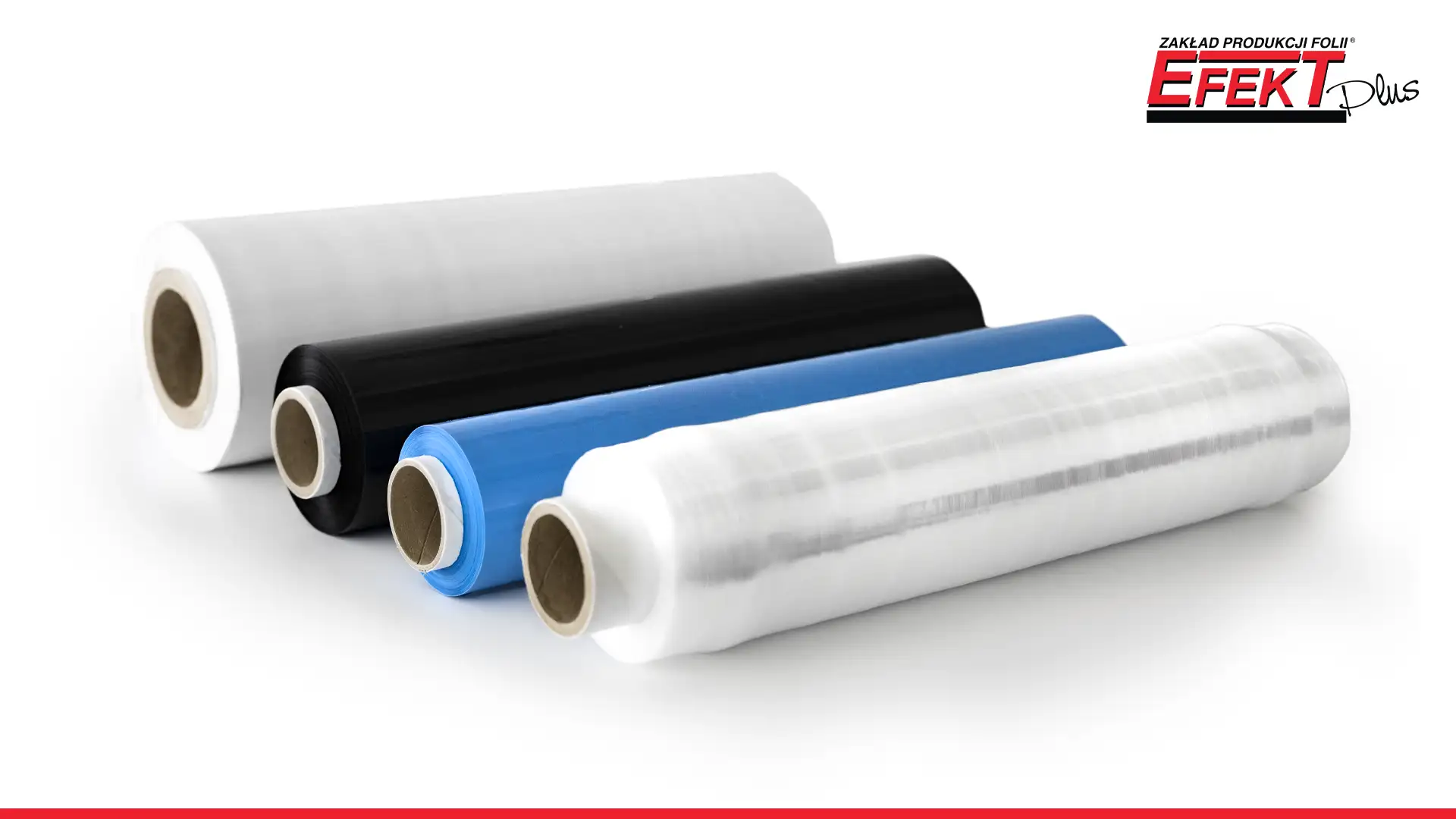

Stretch films of our production in different colours. From left: white machine film, black hand film, blue hand film and transparent pre-stretch film.

Black, white or blue stretch film?

Coloured stretch films mask products and this is their main advantage. They are flexible and robust materials that protect the load from water or dirt. The films can be suitably enhanced – black and white stretch films are often produced with enhancements, including UV additives, making the material resistant to sunlight. The colour of the stretch film also affects the internal temperature of the load. Black films show a greater tendency for packaged products to heat up. White films reflect light better, so the internal temperature of the load is lower.

Pallet wrapped in blue stretch film. As you can see – the foil completely masks the contents of the load.

Specifications of coloured stretch film

Coloured films must be of the right thickness to effectively mask the load, which is why we offer products with a thickness of 15-35 µm and in quality classes from Standard to Power. We produce both coloured hand stretch films (including coloured mini rap films), coloured machine stretch film and coloured jumbo packaging films. Full specifications of the products offered can be found in the product sheets. We invite you to take advantage of our offer and contact our specialists.