Advanced machinery and many years of experience in the production of stretch film allow us to offer technologies that are unheard-of by other manufacturers. These are innovative solutions dedicated to specific types of film. The availability of a given technology should be confirmed directly with the Customer Service Department.

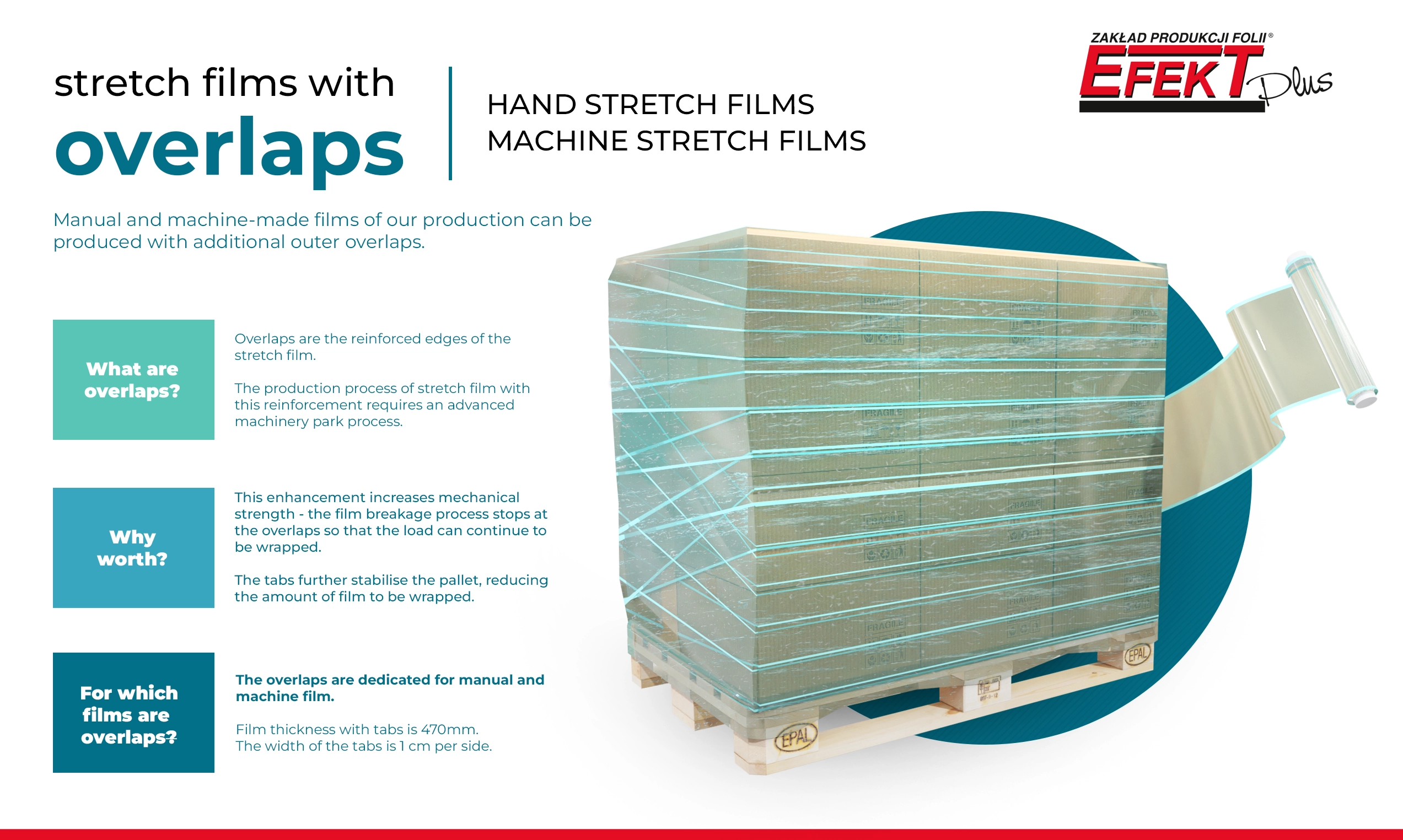

Stretch film with overlaps

Manual and machine films of our production can be made with additional external overlaps.

This is a special process which involves folding the film, reinforcing its edges. This enhancement increases the mechanical strength – the peeling process stops at the overlaps preventing further breaking of the film. Our technology reduces usage of material to achieve proper stabilisation, thus reducing the cost of wrapping the load.

The overlap width is 1 cm per side. Films with this reinforcement are available in a width of 470mm. They are dedicated to each quality class of our stretch film range, in thicknesses from 8µm – 35µm.

M50 Technology

M50 is the first and only 50-layer film on the market with very high puncture and tear resistance. The film core resembles a mesh structure, which has a significant impact on the strength and excellent load stabilisation. It is dedicated to machine stretch film and Jumbo stretch film.

SEVEN Technology

SEVEN Stretch Film is made of 7 layers. The new technology enables the production of microstretch films with a thickness of 8 µm. Seven Film is characterized by enhanced barrier and durability. The possibility of producing such thin films that meet the quality and strength parameters similar to films in the range of 17-20 µm allows to reduce wrapping costs by up to 50%.

E7 Technology

E7 Stretch Film was created in accordance with the idea of sustainable development. It is a pro-ecological product. The special feature of this film is the use of regranulate in its production.

Efekt Stretch Plus Technology

Polyolefin Film made of 5 layers, manufactured on a unique six-meter line. The films manufactured in this technology have enhanced parameters for classic stretch film in the standard class.

Slippery films dedicated to the close storage of products.

Slippery films dedicated to the close storage of products.  Films resistant to low temperatures.

Films resistant to low temperatures. Food safe films that may come into direct contact with it.

Food safe films that may come into direct contact with it. The material shows increased resistance to UV radiation.

The material shows increased resistance to UV radiation. Increased stickiness of the film, a solution dedicated to confectioners.

Increased stickiness of the film, a solution dedicated to confectioners. The coloured films effectively conceal the contents of the cargo.

The coloured films effectively conceal the contents of the cargo.