What are PCR regranulates

PCR (Post-Consumer Recycled) regranulates are an innovative solution that introduces sustainable practices into the stretch film production process. In this article we take a look at what regranulates are, how they are produced and the environmental benefits they bring.

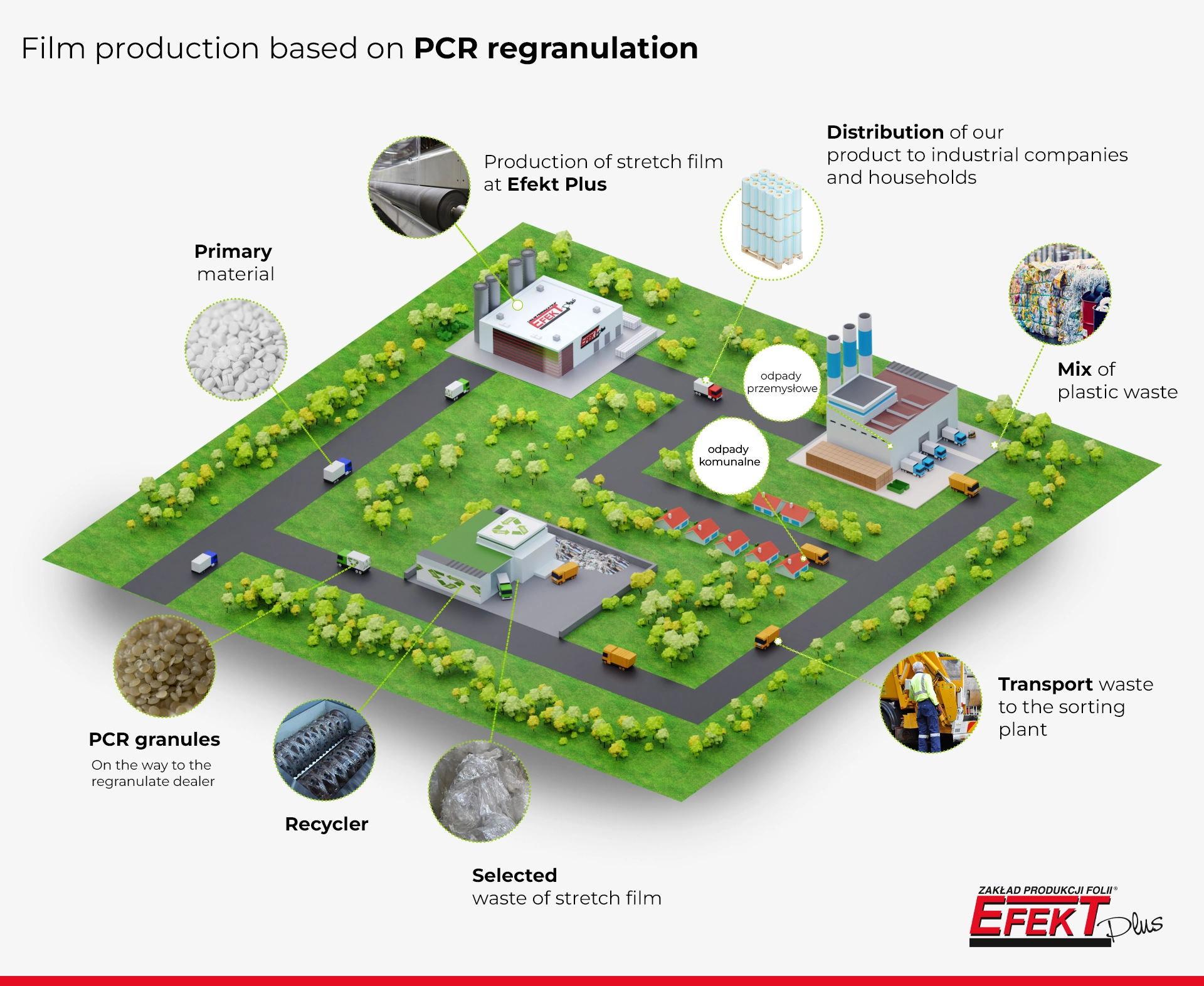

PCR materials are derived from the recycling of post-consumer waste. The process of producing PCR material involves collecting, sorting, washing and processing the waste to produce a raw material ready for reuse. The first step in the production of PCR regranulate is the proper sorting of waste fractions from industry as well as households. This process aims to separate valuable plastics that will be used to produce regranulate. This is followed by a cleaning stage, in which the waste is thoroughly cleaned, removing any impurities and undesirable substances. After thorough cleaning, the selected waste is regranulated. In this process, new granulate is created that has similar parameters to the original raw material, created from fossil materials.

PCR regranulate in its final form.

PCR regranulate has similar physical, chemical and mechanical properties to LLD-PE granulate, making it an effective means of producing eco-friendly film.

Recycling, the environment and regranulates

The use of PCR regranulates in the production of stretch film has many benefits. Firstly, it reduces the use of raw materials from non-renewable sources. Secondly, it reduces the amount of plastic waste that ends up in landfills or is released into the environment. By consciously recycling and reusing PCR regranulates, the consumption of oil and natural gas, which are the basic building blocks of plastics, is reduced. This, in turn, contributes to reducing greenhouse gas emissions and environmental impact. According to available MLC studies by Sphera, the use of PCR regranulates reduces CO2 reduction by up to 46%.

Properties of eco-friendly stretch film

The use of high-quality LLD-PE (low rope density polyethylene) regranulates in the production of stretch film has many benefits, both from a raw material efficiency and environmental point of view. Selected and high-purity LLD-PE regranulates can replace virgin granulates without losing the properties of the final product, which is still fully recyclable. It is also worth mentioning that only highly selected PCR granulates are comparable in quality to virgin raw material.

They have similar physical and chemical properties. Thus, this means that Recowrap™ PCR film is just as durable and strong as traditional stretch films of our production. PCR regranulates therefore have huge potential in the stretch film industry. They offer the opportunity to create more sustainable and environmentally friendly products, while helping to reduce plastic waste and the consumption of primary raw materials.

Acting in accordance with the principles of sustainability, PCR granulates are an innovative solution that contributes to the reduction of negative environmental impacts, while enabling the production of durable and long-lasting stretch films. In summary, the use of high-quality LLD-PE regranulates in the production of PCR-based stretch films brings numerous benefits, such as reducing the use of virgin granules, maintaining the properties of stretch films, reducing negative environmental impact and reducing greenhouse gas emissions. Thus, we encourage the sorting of waste for reuse in subsequent production (so-called closed loop).

New ecological stretch film in our offer

We are very pleased to introduce to you the latest product that has just joined our wide range – Recowrap™ PCR stretch film! This innovative stretch film is another step in our mission to help protect the environment and promote sustainability. What makes Recowrap™ PCR stretch film stand out from other solutions on the market? First and foremost, it has been manufactured using the latest technology, making extensive use of recycled raw materials. This means the product has less impact on the planet, reducing waste and raw material consumption. The high quality and durability of stretch Recowrap™ film make it ideal for packaging a variety of products. Whether you need to secure pallets of medical or industrial products, our film easily conforms to a variety of shapes and sizes, providing protection and stability during transport.

By using Recowrap™ stretch film, you not only take care of your business, but also actively support the idea of sustainability. By using recycled raw materials, we reduce plastic waste, helping to reduce the burden on the environment. We invite you to take advantage of our new offer and join the ranks of conscious businesses that invest in environmentally friendly products. By choosing Stretch Recowrap™ film, you are showing that care for the planet can and should go hand in hand with excellent quality and functionality.