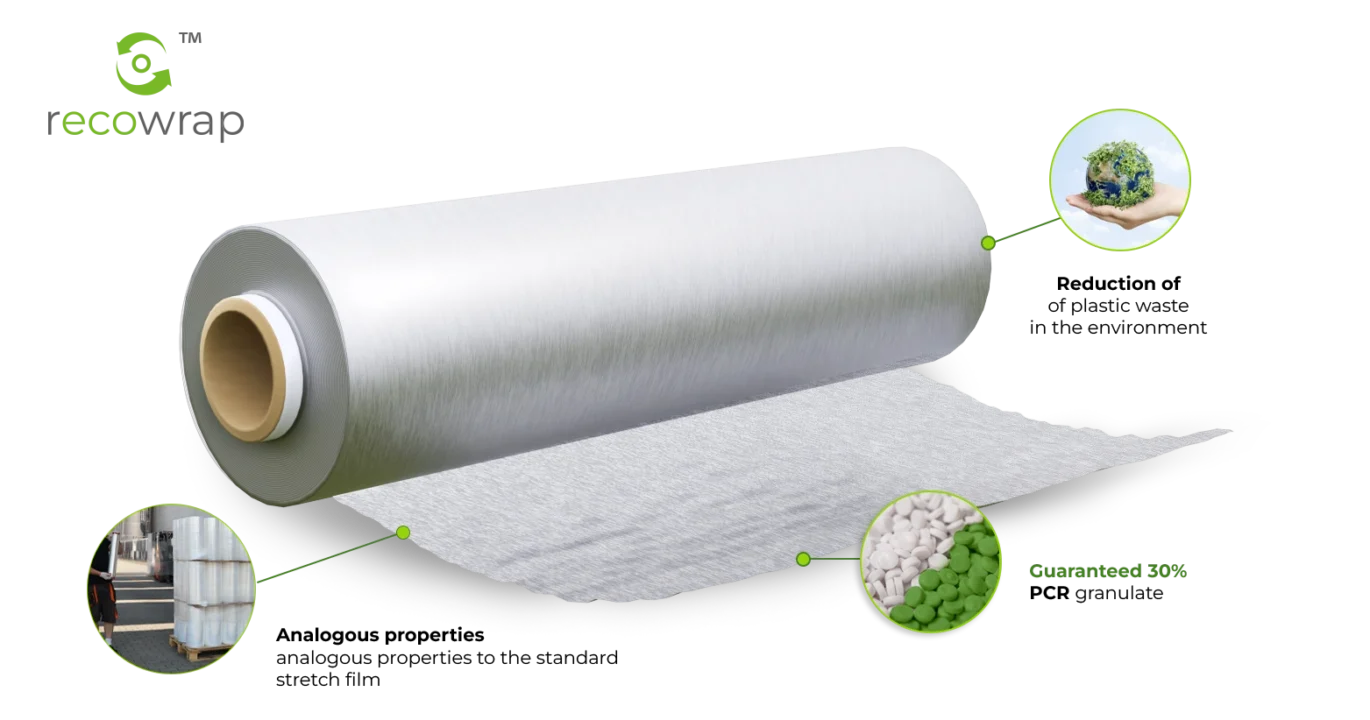

Recowrap™ was developed using post-consumer PCR regranulate (guaranteed min. 30% recycled). It is an environmentally friendly stretch film that requires less virgin plastic used in the production process. Thus, Recowrap™ indirectly contributes to the reduction of plastic waste in the environment. PCR stretch film is available as hand film, machine film, jumbo film and in a small roll – as Mini Rap.

About

Recowrap™ stretch films are flexible and as puncture-resistant as classic stretch films. Recowrap™ represents a further step forward towards environmentally friendly packaging, which indirectly contributes to the protection of the environment – the product is produced according to sustainable development (closed production cycle). The environmentally-friendly film is currently available in a transparent version and in a standard quality class.

Specification

Recycled 30% stretch film

| Type of stretch film | Hand stretch PCR | Mini Rap PCR | Machine stretch PCR | Jumbo stretch PCR |

| Thickness | 17-35 µm | 17-35 µm | 17-35 µm | 17-35 µm |

| Width | 250, 400, 500 mm | 100, 125 mm | 250, 400, 500 mm | 400, 500 mm |

|

Net weight |

0,7 – 4,5 kg | ND | 5 – 25 kg | 26 – 55 kg |

| Stretchability grade | Standard | Standard | Standard | Standard |

| Colour | transparent | transparent | transparent | transparent |

It is possible to manufacture stretch film to a non-standard specification. To do so, please contact the Sales Department to discuss the details.

Use

Recowrap™ PCR stretch film is used in a variety of industries such as logistics, transport, manufacturing, warehousing and many others. Choosing a film based on PCR regranulates is a commitment to sustainability, which is based on the use of renewable materials (recyclates).